Previous

Next

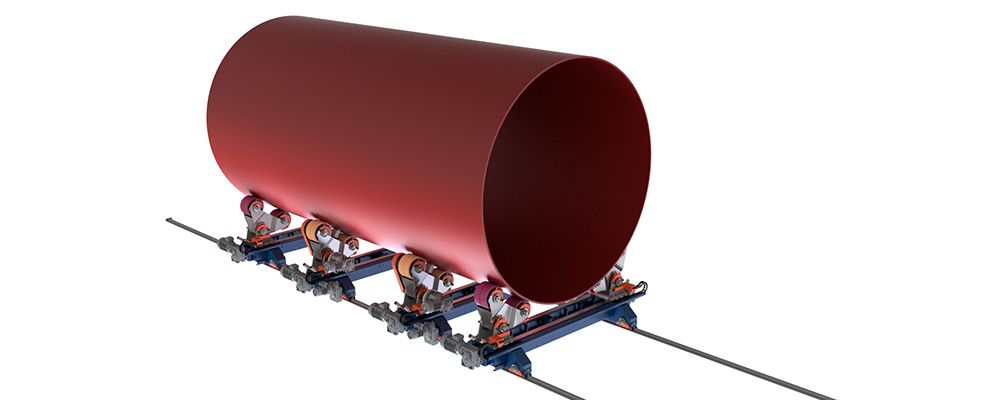

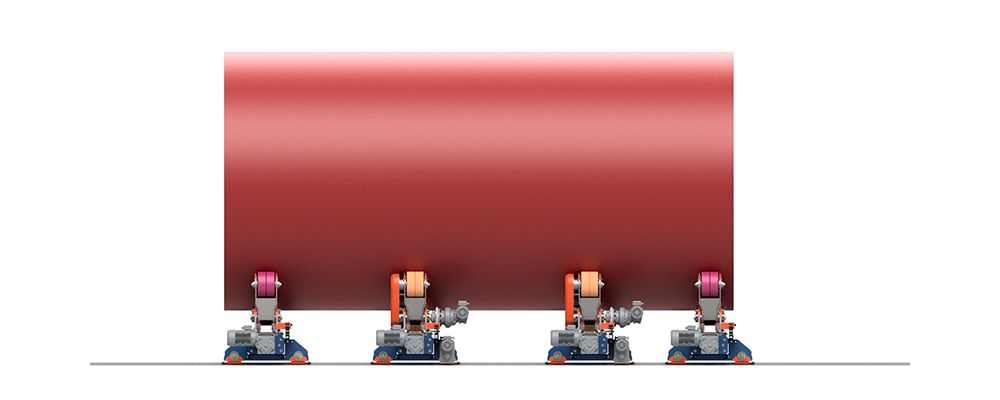

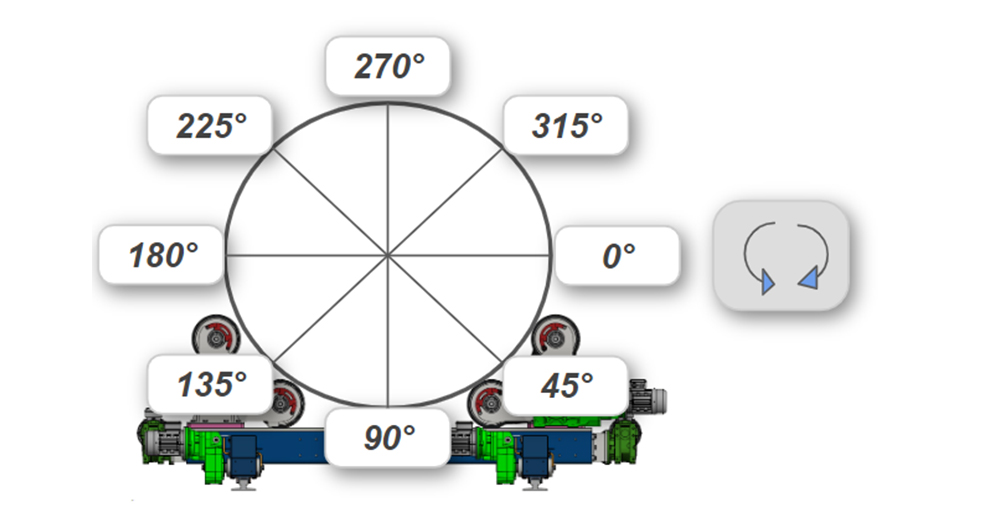

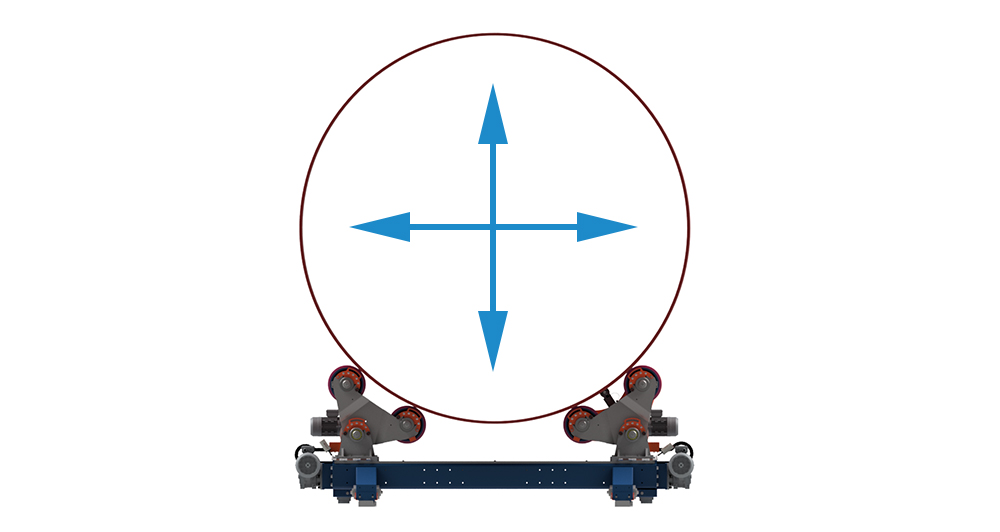

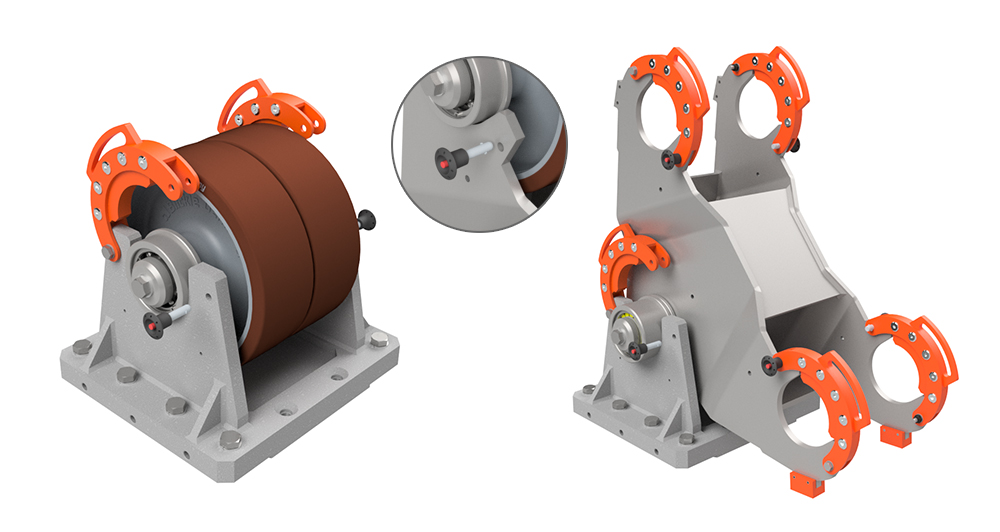

The rotator’s primary purpose is to automate the welding process and to help in the toolless alignment of cylinder sides.

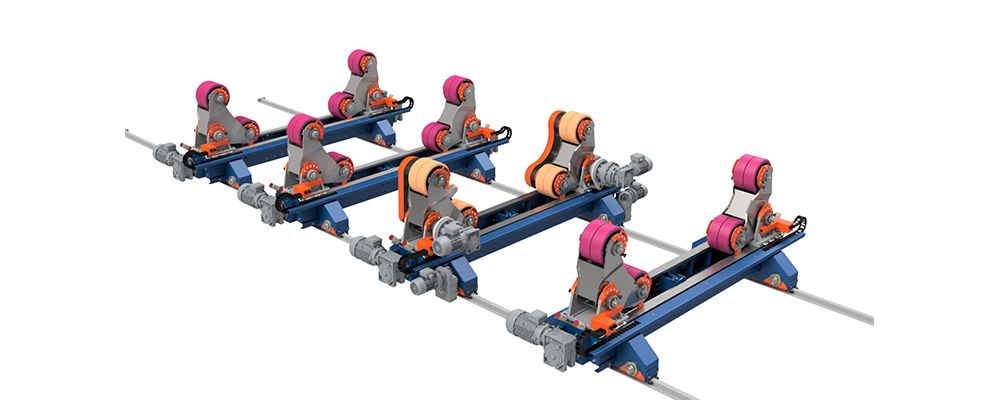

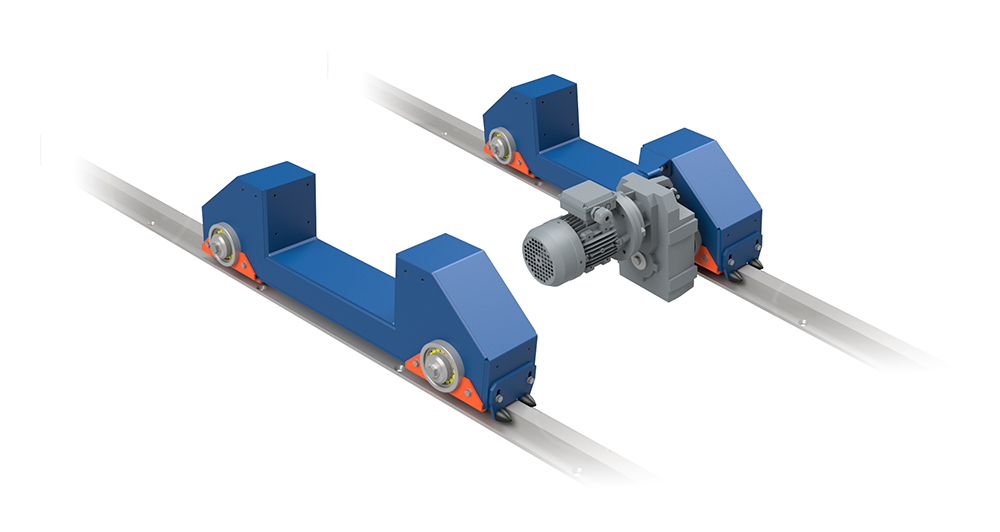

The heads can be moved to the side independently from each other or in pairs, and thus, they are able to correct the misalignment of cylindrical bodies without any intervention from humans or from other machines. The controller can be connected to welding systems, like Column & Boom, which allows the automation of welding processes.

The number of driven and undriven rotators can be chosen in accordance with task of the current work process.

Ø 500 - 5000 mm